The High-precision Full-Automatic Laminating machine is used for laminating thin paper,paperboard, grey board and coated paper, etc.

· Model:HLK-800/HLK-1207/HLK-1210/HLK-1410

· Power:220/380v12kw

· Laminate errpr:±0.5mm

Product Features

Product FeaturesScope Of Application:

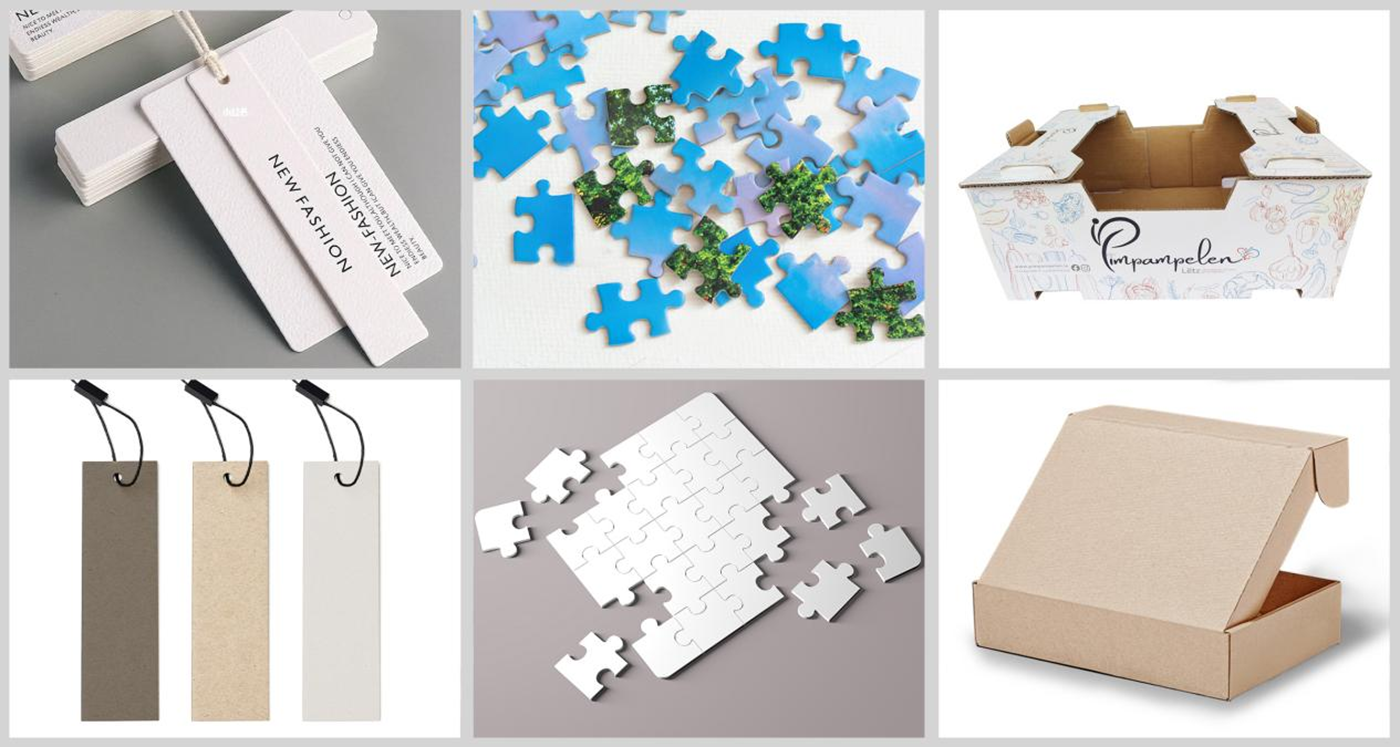

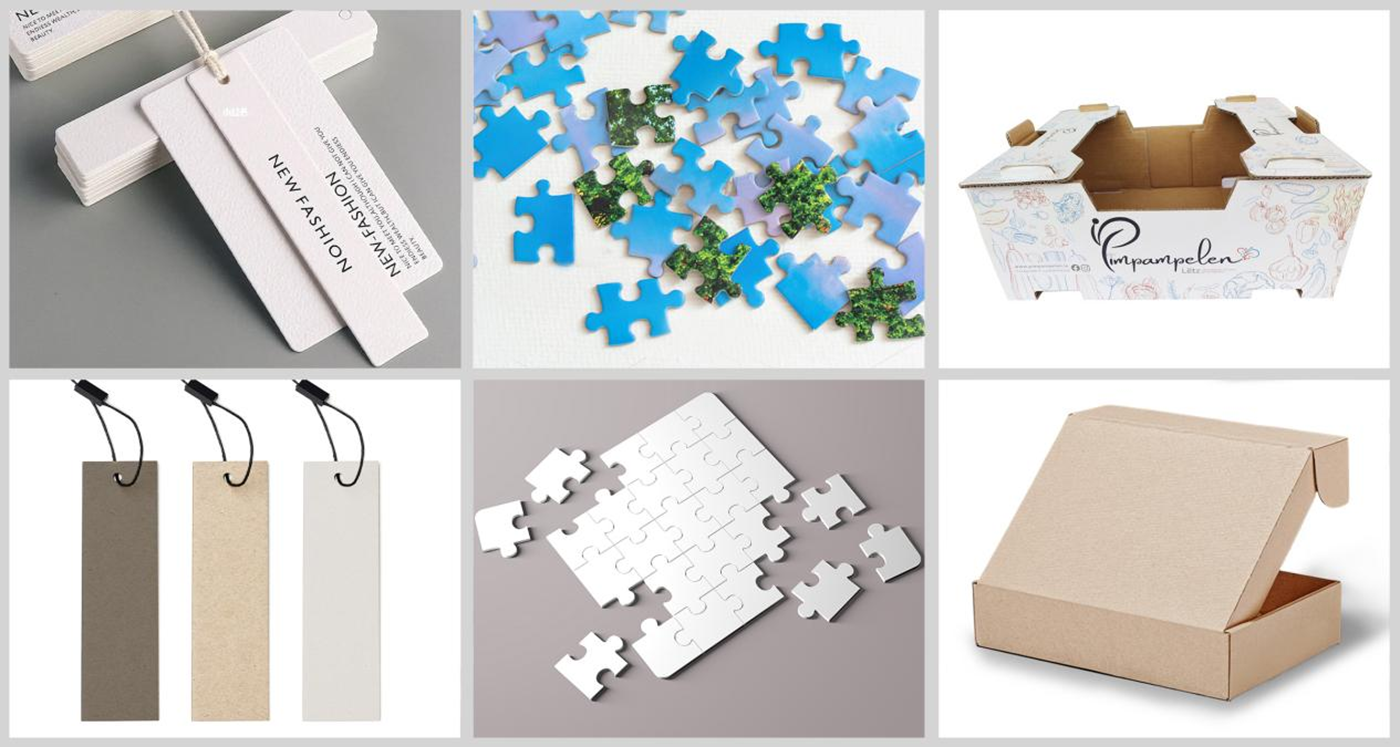

The High-precision Full-Automatic Laminating machine is used for laminating thin paper,paperboard, grey board and coated paper, etc. It can meet the special processing requirements of double-sided printing and lamination of thin paper and thick paper. High laminating accuracy, no deformation before and after lamination. It is suitable for the processing of wine box, shoe box, tag, elevator, toy, gift box and exquisite packaging products, with high flatness, high precision and good hardness.

Performance Feature :

◆ Originality Paper dynamic calibration synchronization system

◆ Double-notch E-shaped design allows the laminated paper to be pushed in with a trolley.

◆ Front suction top feed paper feeding system, size changeover without adjustment, easy to operate

◆ The shake loose type take-up system can shake loose the overlapping products and then push them to ensure a neat and smooth take-up.

◆ The rotation speed and pressing length are electrically adjusted for convenient conversion

◆ PLC computer control system can automatically detect operation conditions,abnormal conditions, maintenance conditions and work records

◆ High precision coating system, automatic liquid level control, can accurately adjust the coating amount according to the paper demand to ensure uniform gluing.

Technical Parameters

Technical Parameters

| Model | HLK-800 |

| Max.sheet size | 860*680mm |

| Min.sheet size | 350*270mm |

| Power | 220/380v12kw |

| Thickness of upper paper | 120-900g/㎡ |

| Thickness of bottom paper | 180-800g/㎡ |

| Laminate errpr | ±0.5mm |

| Operation space | 3m*12m |

| Max.speed | 100pcs/min |

| Weight | 6500kg |

| Dimension | 9*1.6*2.2m |

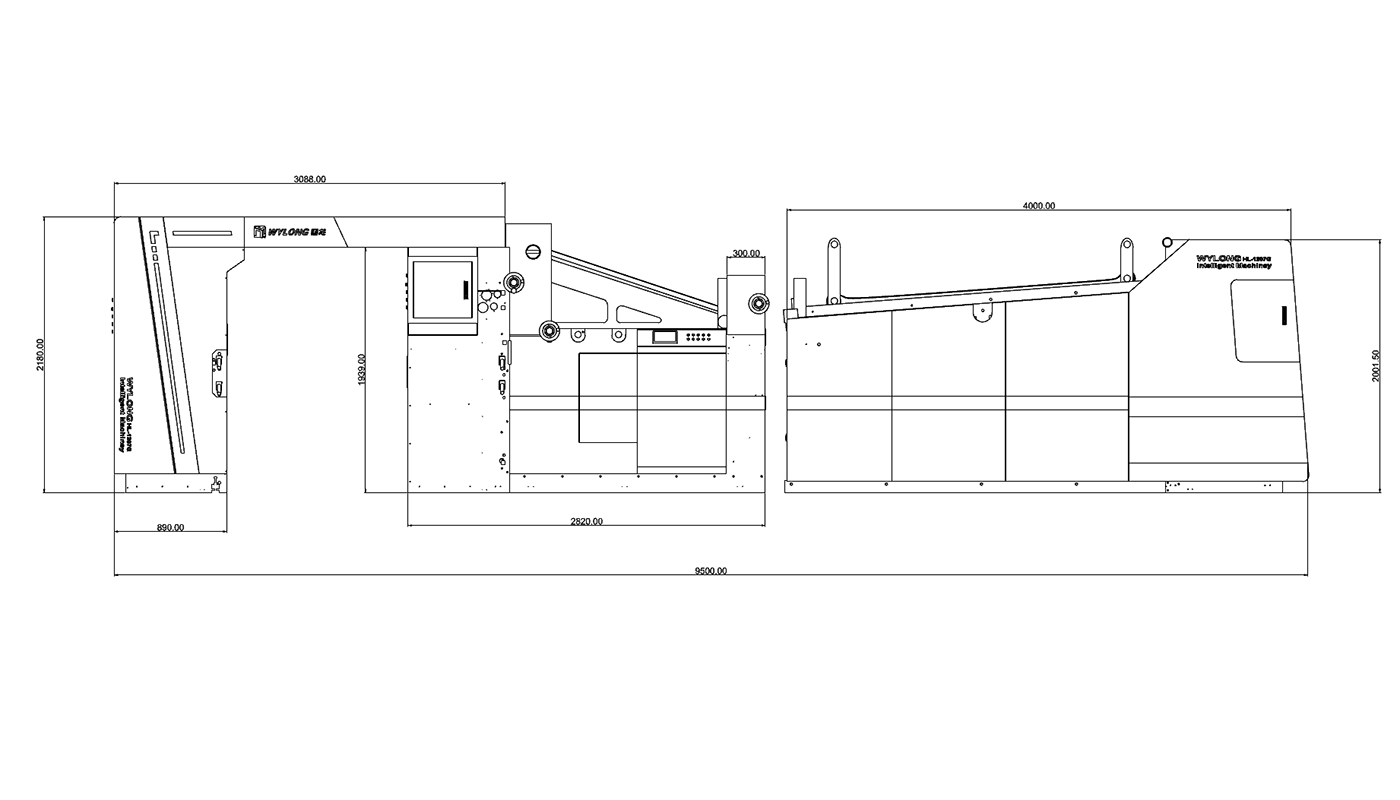

2DSketch:

Samples :

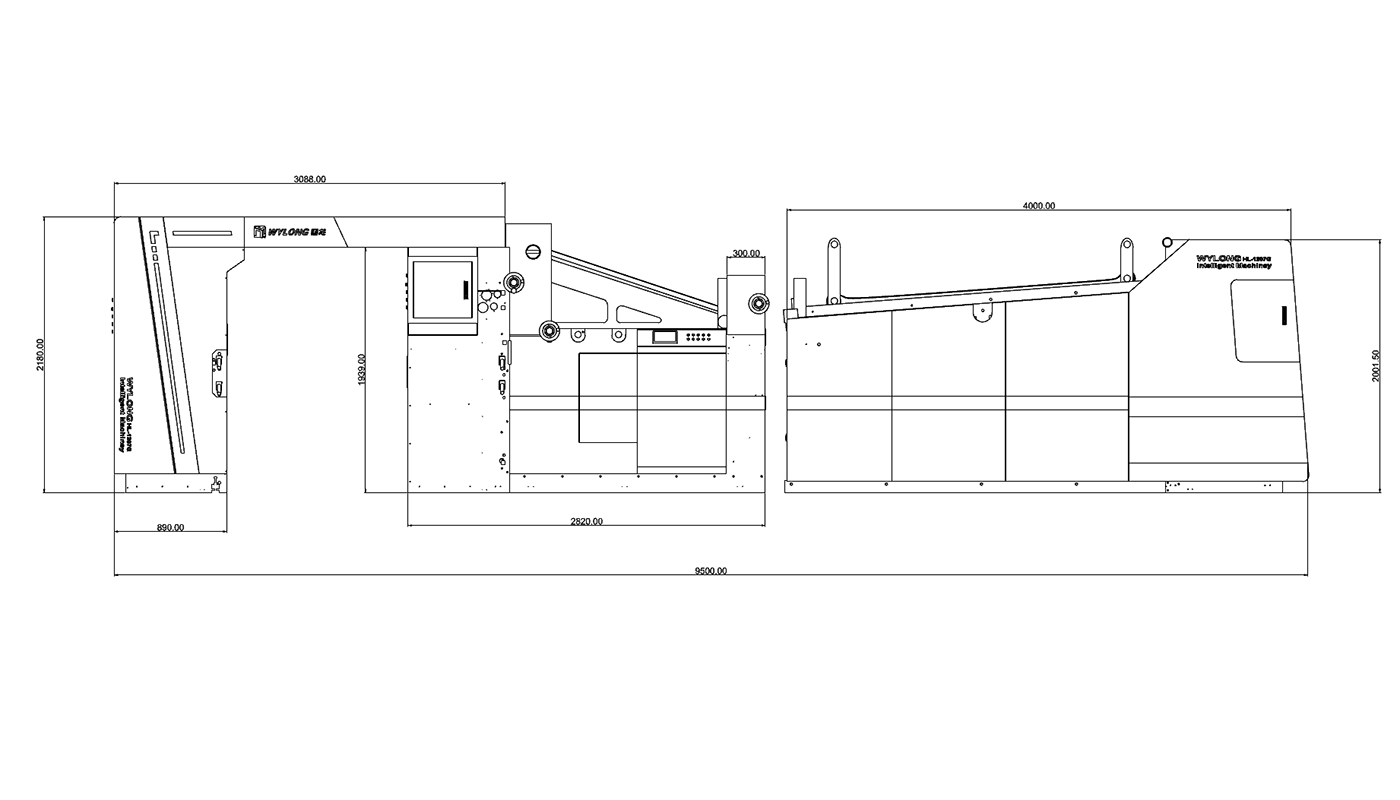

| Model | HLK-1207 |

| Max.sheet size | 1200*700mm |

| Min.sheet size | 500*280mm |

| Power | 220/380v12kw |

| Thickness of upper paper | 120-1000g/㎡ |

| Thickness of bottom paper | 200-1500g/㎡ |

| Laminate errpr | ±0.5mm |

| Operation space | 3m*12m |

| Max.speed | 100-150pcs/min |

| Weight | 7000kg |

| Dimension | 9*1.9*2.2m |

2DSketch:

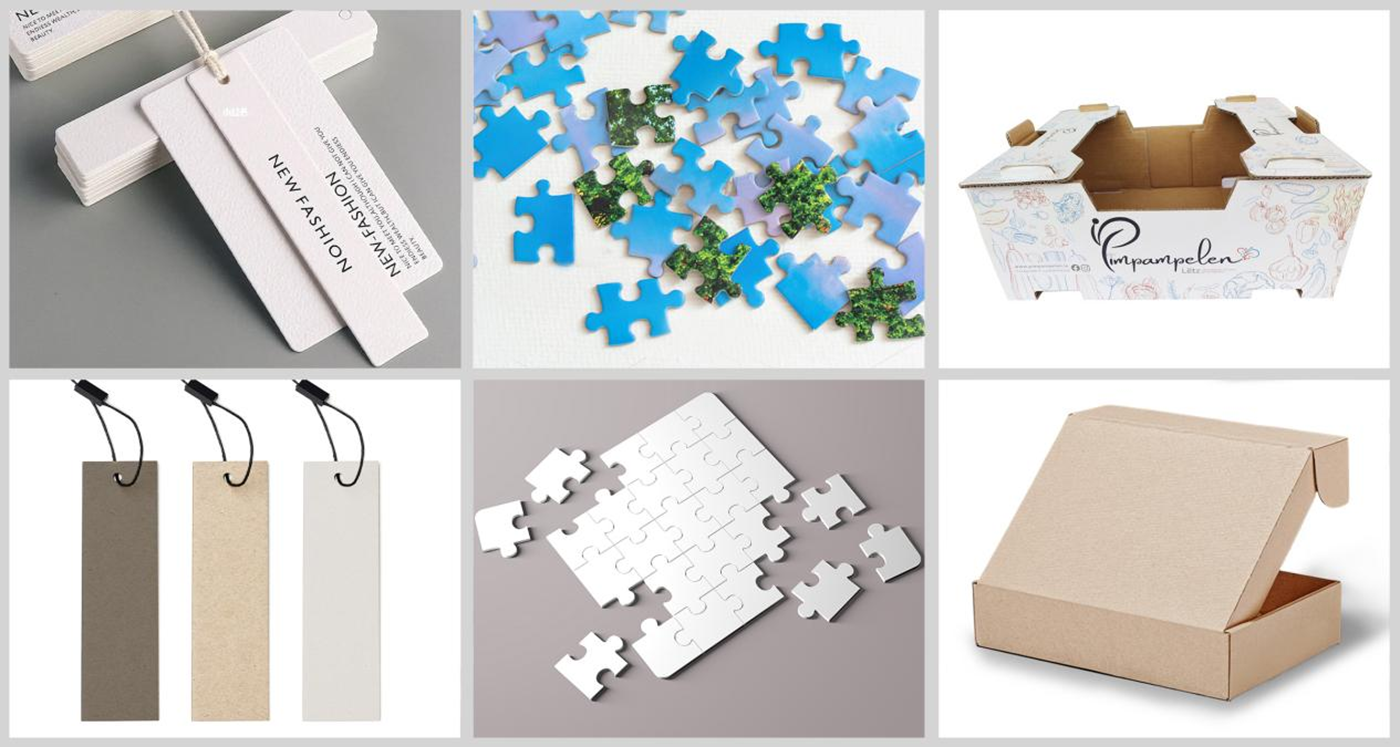

Samples :

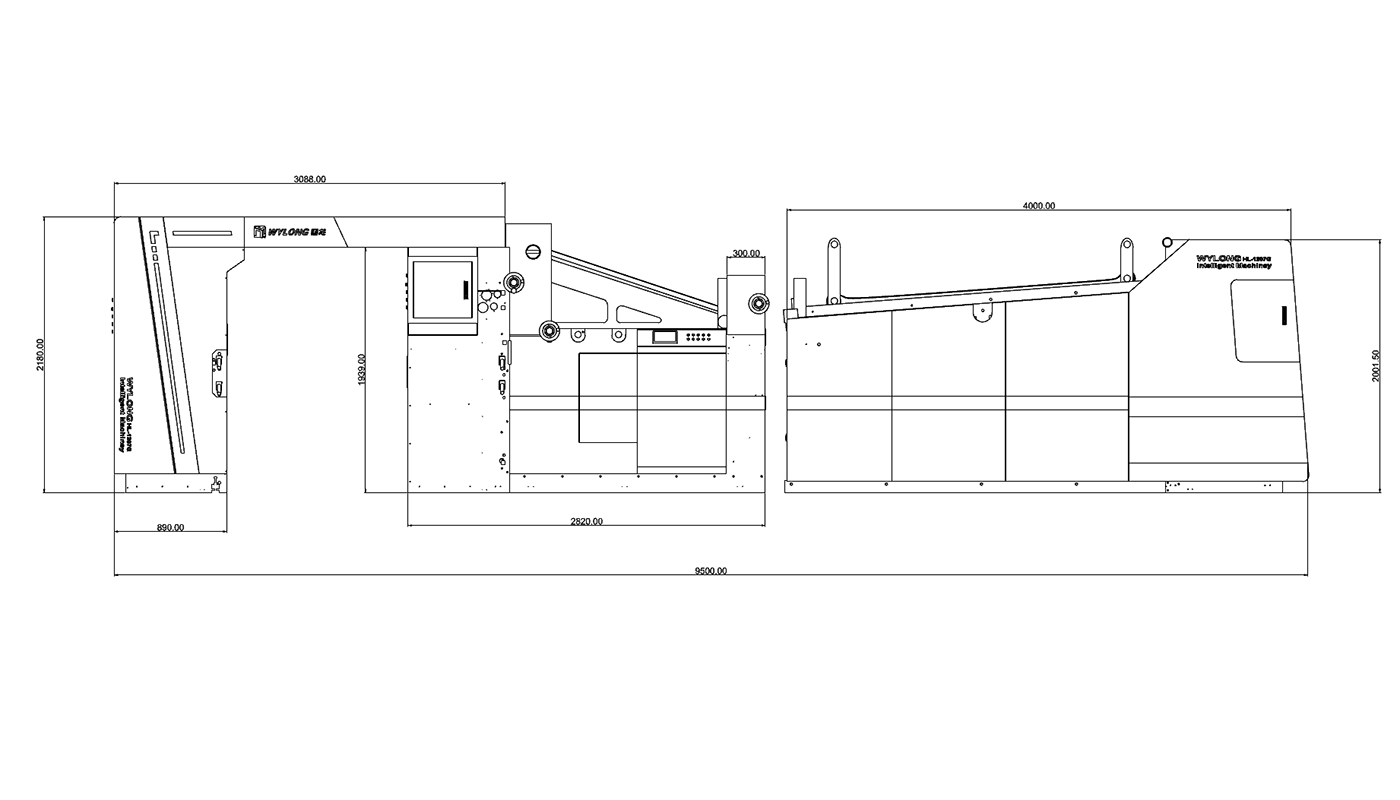

| Model | HLK-1210 |

| Max.sheet size | 1200*1000mm |

| Min.sheet size | 500*280mm |

| Power | 220/380v12kw |

| Thickness of upper paper | 120-1000g/㎡ |

| Thickness of bottom paper | 200-1500g/㎡ |

| Laminate errpr | ±0.5mm |

| Operation space | 3m*12m |

| Max.speed | 100-150pcs/min |

| Weight | 7000kg |

| Dimension | 9*1.9*2.2m |

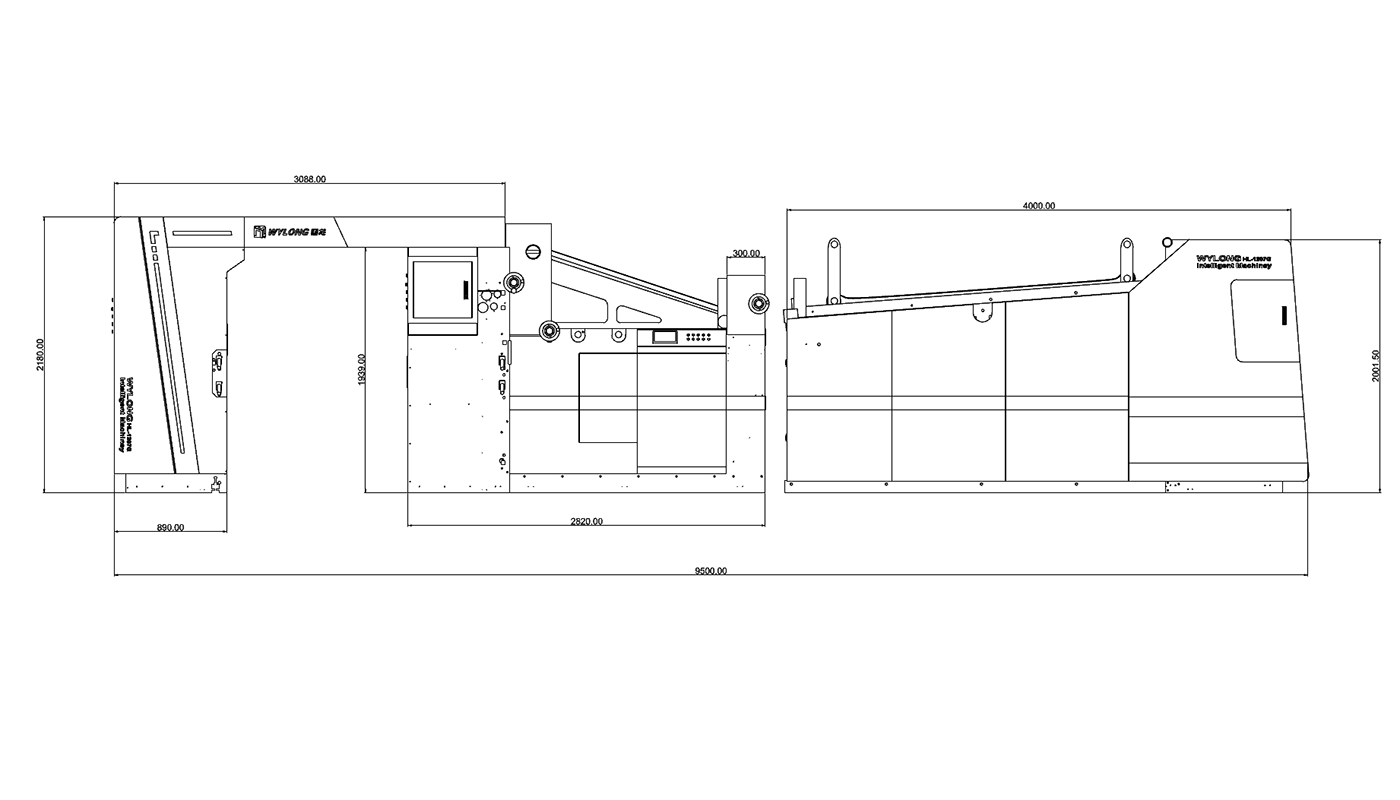

2DSketch:

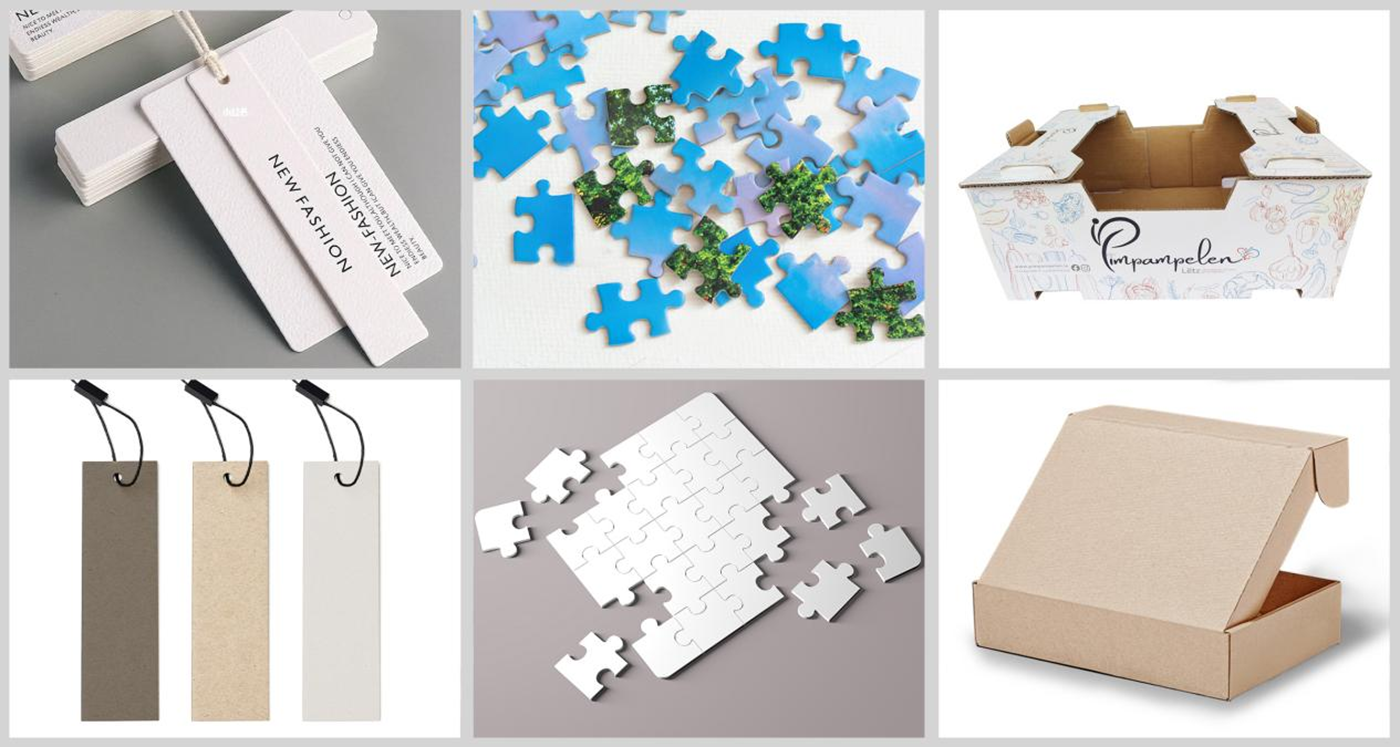

Samples :

| Model | HLK-1410 |

| Max.sheet size | 1350*1000mm |

| Min.sheet size | 500*280mm |

| Power | 220/380v12kw |

| Thickness of upper paper | 120-1000g/㎡ |

| Thickness of bottom paper | 200-1500g/㎡ |

| Laminate errpr | ±0.5mm |

| Operation space | 3m*12m |

| Max.speed | 100-150pcs/min |

| Weight | 7000kg |

| Dimension | 9*1.9*2.4m |

2DSketch:

Samples :

Faq

FaqQ1: Do you have different models for each machine?

Reply: Yes, we have different models and we can make the machine according to your requirements.

Q2: What is the production time?

Reply: Normally we need around 45 days.

Q3: What service you can offer after we buy the machine?

Reply: We have a few experienced technicians who can help to install and test running the machine anytime overseas. Moreover, our own export personel

will give you the service support after buying the machine. As long as you have any questions, we will try our best to help you.

Q4: What about the payment terms?

Reply: We accept T/T. 30% as deposit and 70% balance should be paid before delivery. We can also accept 100% confirmed irrevocable L/C at sight.

Overview

Overview

Wylong provides different type of thermoforming machines. MF serial is two stations thermoforming machine is forming first, followed by a post trim press to separately trim the finished product to the packing table for packaging, also configure with scrap granulation automatically in-line. MT serial form trim in place one station machine has a small or medium size of forming bed to produce maximum 40 forming/trimming cycle speed. It is suitable for all typical thermo plastic materials, particularly for products that require precise trim tolerances such as deep draw PP containers or cups. MC series is a fully automatic thermoforming machine, designed to specifically meet the demands of production in multi-station operation by steel rule die cutting technology.