High standardization and precise cutting technology significantly improve the efficiency and quality of food packaging.

· Sheet Materials:PP,PET,PVC,PS,PLA

· Sheet Thickness:0.2 – 2 mm

· Forming Area:750 * 650 mm

Product Features

Product FeaturesApplications :

Food Packaging: The Multi Station Thermoforming Machine produces trays, lids, and containers with high standardization and cutting accuracy, enhancing food packaging efficiency and quality.

Industrial Use: This versatile Multi station thermoforming machine forms durable parts and components with flexible production capabilities, ensuring exceptional reliability and precision in industrial applications.

Medical Industry: Create high-quality sterile packaging solutions with the Multi Station Thermoforming Machine, which offers strong, durable materials and user-friendly software for precise control in medical packaging.

Consumer Goods: Utilize the Multi station thermoforming machine to manufacture clamshells, flower pots, and nursery trays, benefiting from the 4-post press system for balanced forming and cutting forces.

Custom Manufacturing: The Multi Station Thermoforming Machine supports custom manufacturing, enabling the production of tailored products across various industries with its robust design and consistent performance.

Product Characteristics :

· High standardization and precise cutting technology significantly improve the efficiency and quality of food packaging.

· Having flexible production capabilities ensures excellent reliability and precision in industrial applications.

· The 4-pillar press system ensures a balanced distribution of forming and cutting forces.

· Support personalized customization.

· User friendly software for controlling every operation and task.

Technical Parameters

Technical Parameters

| Model | ZHD-750/650 |

| Sheet Materials | PP,PET,PVC,PS,PLA |

| Sheet Thickness | 0.2 – 2 mm |

| Forming Area | 750 * 650 mm |

| Width of Sheet | 500 – 800 mm |

| Forming Depth Upper Mould | 130mm |

| Speed | 10-35 moulds/min |

| Heating Power | 150kw |

| Total Installed Power | 180kw |

| Feeding Servo Motor Power | 4.5 kw |

| Forming Servo Motor Power | 5.5kw x 2 |

| Cutting Motor Power | 7.5kw x 2 |

| Air Consumption | 0.5-0.8 bar |

| Dimension | 11500 * 2400 * 2200 mm |

| Weight | 22000 kg |

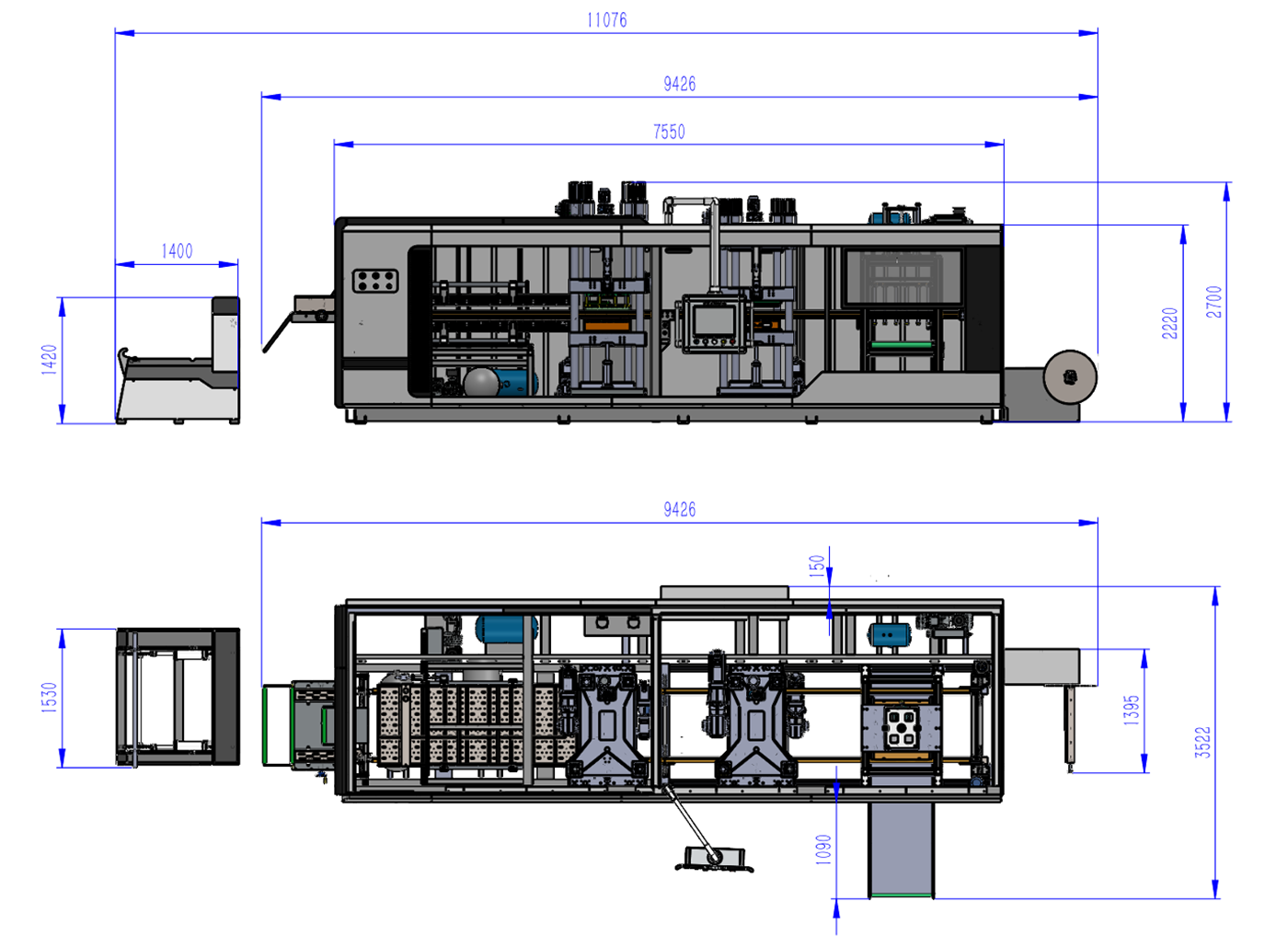

2DSketch:

Samples :

| Model | ZHD-750/650 |

| Sheet Materials | PP,PET,PVC,PS,PLA |

| Sheet Thickness | 0.2 – 2 mm |

| Forming Area | 750 * 650 mm |

| Width of Sheet | 500 – 800 mm |

| Forming Depth Upper Mould | 130mm |

| Speed | 10-35 moulds/min |

| Heating Power | 150kw |

| Total Installed Power | 180kw |

| Feeding Servo Motor Power | 4.5 kw |

| Forming Servo Motor Power | 5.5kw x 2 |

| Punching Servo Motor Power | 7.5kw x 2 |

| Cutting Motor Power | 7.5kw x 2 |

| Air Consumption | 0.5-0.8 bar |

| Dimension | 12500 * 2400 * 2200 mm |

| Weight | 24000 kg |

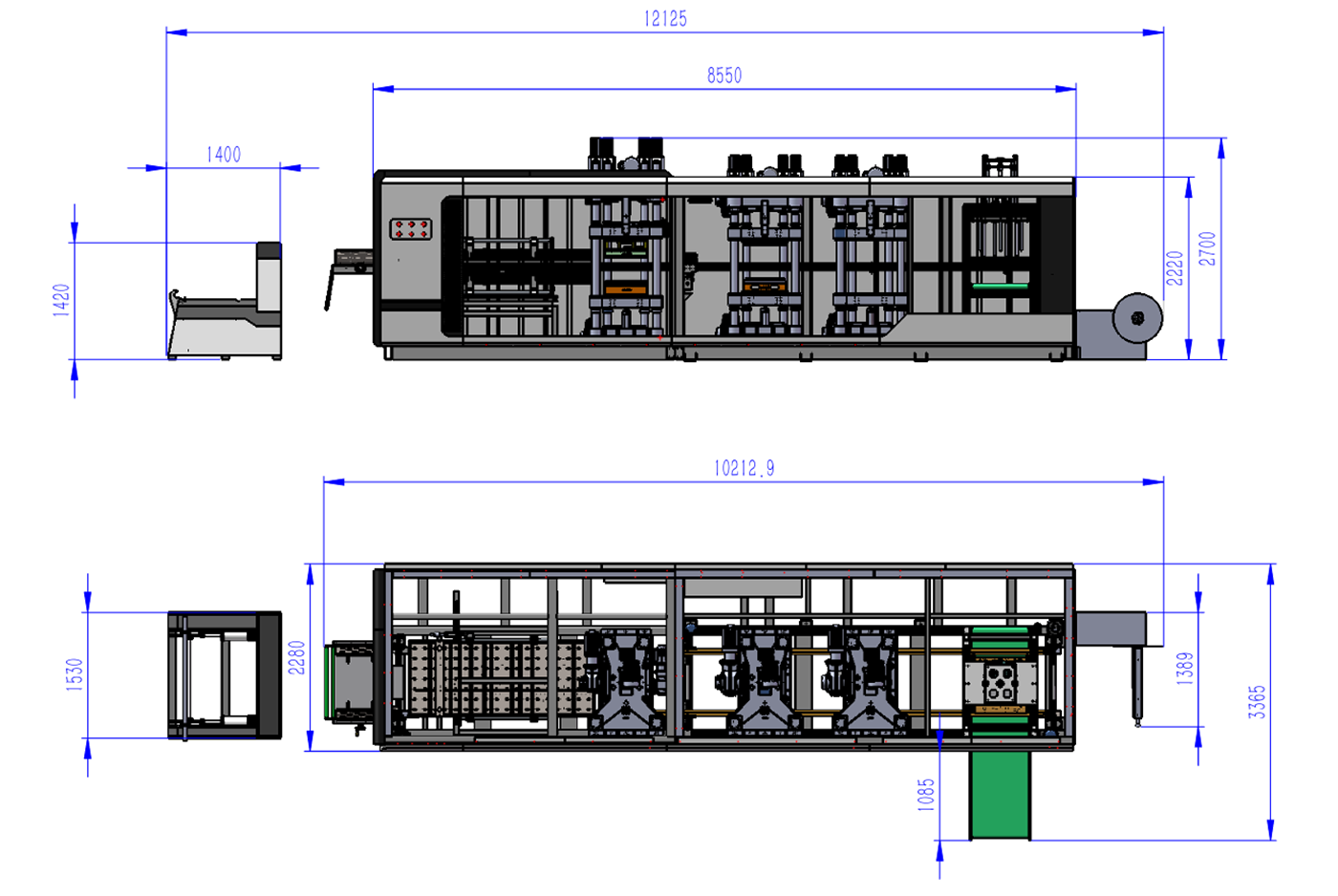

2D Sketch :

Samples :

Faq

FaqQ1: Do you have different models for each machine?

Reply: Yes, we have different models and we can make the machine according to your requirements.

Q2: What is the production time?

Reply: Normally we need around 60 days.

Q3: What service you can offer after we buy the machine?

Reply: We have a few experienced technicians who can help to install and test running the machine anytime overseas. Moreover, our own export personal will give you the service support after buying the machine. As long as you have any questions, we will try our best to help you.

Q4: Should the customer send the sample ?

Reply: Yes, If the customer has no samples, please send a drawing or a photo of the sample, and let us know the size. Then we will send the drawing for your confirmation.

Q5: What about the payment terms?

Reply: We accept T/T. 30% as deposit and 70% balance should be paid before delivery. We can also accept 100% confirmed irrevocable L/C at sight.

Q6: What is the capacity of the thermoforming machine?

Reply: The accurate capacity depends on the size and material of the products.

Q7: What kinds of products can the thermoforming machine produce?

Reply: It can produce all kinds of disposible plastic cup lid, bowls, plate, boxes,egg tray, food container, etc.

Overview

Overview

Wylong provides different type of thermoforming machines. MF serial is two stations thermoforming machine is forming first, followed by a post trim press to separately trim the finished product to the packing table for packaging, also configure with scrap granulation automatically in-line. MT serial form trim in place one station machine has a small or medium size of forming bed to produce maximum 40 forming/trimming cycle speed. It is suitable for all typical thermo plastic materials, particularly for products that require precise trim tolerances such as deep draw PP containers or cups. MC series is a fully automatic thermoforming machine, designed to specifically meet the demands of production in multi-station operation by steel rule die cutting technology.